Gluten Free Home Brewing Blog

Increase Efficiency By Improving Your Grist

This year has been one of growth and expansion at Bierly Brewing, a dedicated gluten free brewery in McMinnville, Oregon, and we’ve been very focused on bringing in new equipment that will help us meet our production goals with quality and efficiency. We brew all of our beer two barrels at a time, but until recently our grain bills were limited to 42 pounds or less. At this scale, we were able to get by with a corona-style mill to grind all of our grain. We used a Wondermill Jr. and it came with both a stone mill set and a steel mill set.

In our experience, a corona-style mill has three main disadvantages.

- It is impossible to set the mill gap to the same settings each time, which means grist size is inconsistent from batch to batch.

- The mill crushes the grist unevenly and the grist contains both flour and barely-crushed grain.

- Corona-style mills are very slow and it can take up to an hour to grind a 42 pound grain bill.

In planning for expansion of our all-grain capacity, we identified this mill as a problem point in our process. Using “beer mat math,” we estimated that the time required to mill our new grain bill size of 200 pounds with our corona-style mill would be five hours. We began searching for a mill that would mill 200 pounds within no more than one hour, the time that is required to heat the hot liquor up to strike temperature. Because our grain bills are only 200 pounds, a large, expensive industrial mill was not required and we began researching adjustable roller-type mills as a compromise between cost and speed.

Members of Zero Tolerance Homebrew Club recommended mills from several manufacturers and we began calling different manufacturers to see if they had ever built a mill that could crush millet to the size of 0.5 millimeters or 20 thousandths. Fred Francis from Monster Brewing Hardware had built such a mill and said that he had experimented with both slotted rollers and knurled rollers. In Fred’s opinion, slotted rollers are not ideal for millet because they allow whole grain through the slot as they rotate. Knurled rollers will crush millet, but the standard knurls are too large and the rollers can’t get close enough to crush all of the millet. Fred’s solution was to machine down a set of knurled rollers so that they can be set to a tight gap.

Monster Brewing Hardware offers mills with both two and three rollers. Fred said that an adjustable two-roller mill was better for our application because in a three-roller mill, the millet pours through the first set of rollers anyway. Two-roller mills can be adjusted to mill corn (desirable for some gluten free beers) and they are less expensive than the three-roller mills.

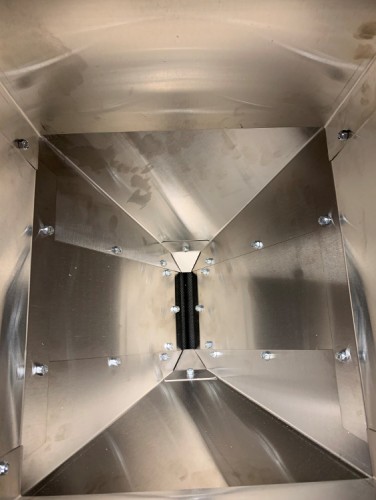

We ordered our mill and have been using it with great success. Milling 42 pounds of grain can be accomplished within 10 minutes, including the time required to change the mill gap settings. We use a feeler gauge and a nut driver to get our mill adjusted and locked down to the same mill gap every time. The size of the grist is consistent, with very little flouring. We’ve been experimenting with the mill gap size to see what effect it has on mash efficiency. Our grain beds have been more “pillowy” with little to no grain bed compaction. If desired, our Monster Mill can be set tight enough to mill grain to flour. In addition to the lack of compaction, we see better rinsing of the grain bed during sparging.

We use a two hour recirculating mash with a low temp rest and then higher temp mash. In order to test the effect of the mill on the outcome, we mashed one batch using the corona-style mill and measured the preboil gravity at 1.054. The preboil gravity of second mash using the Monster Mill was 1.064 with no other changes to the mash regime. Recirculation is easier due to the lack of compaction; the mash doesn’t have to be stirred constantly to keep the liquid flowing. The return to the mash tun is restricted by use of a bypass valve on the RIMS tube in order to keep the pump from drawing too hard on the liquid going through the grain bed and false bottom. With the grist milled with the corona-style mill, the bypass has to be adjusted constantly. With the grist from the Monster Mill, the flow rate is “set it and forget it.”

We use different mill gap settings for different grains. The range that seems to work the best for white proso millet is 0.5-0.6 millimeters (mm). We use red proso millet on occasion and that requires 0.45mm, but otherwise we use 0.5-0.6mm with white proso millet with a single pass through the mill. Crushing buckwheat can also be done in a single pass with similar mill gap settings to millet. Rice requires two passes through the mill because of how hard it is. We start by setting the mill to 0.88mm and running all the rice through at this gap setting to soften it up. We then adjust the mill gap down to 0.7mm and run the rice through again. This sufficiently crushes the grain without destroying the rice hull so as to allow for proper circulation. A note of caution, if you are using a drill to drive the mill, the first run at 0.88mm will require two firm hands on the drill handle. Before we built a stand for the mill, we also put our foot on the wooden mill base to keep it from spinning off the bucket.

Our early testing has been extremely promising. Our overall brewhouse efficiency went from mid-60% to mid-90% with the addition of the mill and some other mash regime changes, which we’ll be writing about in future articles. As far as whether we will ever use our corona-style mill again, we’ve placed it on a very high shelf and don’t plan on bringing it down again. Don’t ask us to send it to you, we wouldn’t want to subject you to its limitations. Buy a roller mill from Gluten Free Home Brewing instead.

~Cheers!